Quality Assurance

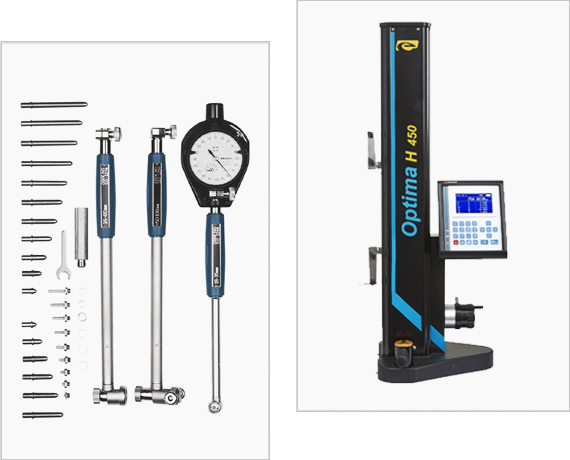

Quality Facilities and Instruments

Quality is the prime focus and the core of all activities

We follow stringent quality control procedures at every stage of manufacturing, right from incoming raw material stage to in-process and finish product stage. Manufacturing of a component involves many setup’s, we carryout approval of each setup by checking the first part of each setup thoroughly as per drawing, this helps us to control. Once all the in-process stages are approved we carryout First Piece Inspection to confirm the component is 100% meeting the drawing specifications and finally after client satisfaction and clearence to go ahead we start the mass production. This is our inbuild quality system and we follow it rigorously, irrespective of whether the client requires First Piece Inspection or not.

We maintain proper identification & traceability of parts during manufacturing and carryout 100% inspection of critical to quality parameters.

COMMITTED TO PROVIDES THE BEST QUALITY SERVICES

At Microtech Tools, Quality is measured and documented at every stage, right from manufacturing to shipment. Our dedicated Quality Control Department ensures tight control on inspection and testing of the finished product to maintain higher and consistent level of quality.

Quality Testing Instruments

We provide a Best quality products as per customer requirment

We believe in having a well defined quality policy and we follow it strictly to deliver a defect-free range of products to tremendous customers. Our team procure quality-approved raw material to manufacture the range of Plain Plug Gauges of various sizes , Thread Plug Gauge of various sizes , Thread Ring Gauges of various sizes, Level Gauge, Precision machined componnets and General Industrial Fabrication work as per costumers requirement.